“I can copy a project I’ve done in EPLAN in minutes, whereas with AutoCAD, you had to deal through a process, copy files, make different folder structures. “With AutoCAD, it took longer to replicate a project,” he says. Often, there are small jobs based on an archived project where only minor modifications to the template are required.

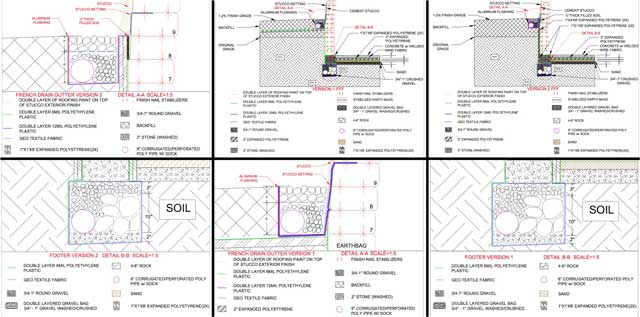

The second one took just two weeks from receipt of the purchase order through design and manufacturing. “We were finishing the design when we were shipping the project,” states Donaldson. Donaldson cites two very similar, large projects, one done in AutoCAD the second, in EPLAN. And all of that is available to the client any time you need it.” Projects are being turned around a lot faster now. “It’s amazing the savings you can have on the fabrication floor. We’re at a point where the shop and my team both trust the drill patterns, the cutouts, the alignment of stuff so work proceeds faster.” He’s a huge advocate of EPLAN Pro Panel’s 3D layouts. “In Pro Panel,” he says, “as long as you set up the (parts) database, all the drill patterns associated with parts, 3D macros associated with parts, it’s just a matter of placing them. When Donaldson’s team worked in AutoCAD, much time went into setting up drill patterns. Comparable, large projects done in one-third of the time “It’s a huge time savings for me.” says Donaldson.

Everything the fabrication crew needs to build the panel is represented in those PDFs. For example, with some small jobs, Donaldson often dispenses with the need to do mechanical drawings by exporting EPLAN Pro Panel’s 3D drill panel views to PDFs. In some cases, his group is skipping entire steps in creating build packages. Dwayne Donaldson, Senior Electrical Designer, lists many areas where EPLAN automation and EPLAN Pro Panel’s 3D layout have been a tremendous upgrade, accelerating project design, often dramatically.

Sold on EPLAN, can't contemplate return to AutoCADģ Phase Power is a full-service manufacturer, distributor and integrator and its engineering department works on all manner and size of projects. Since 3 Phase Power’s engineering group switched from AutoCAD Electrical to EPLAN Electric P8 and EPLAN Pro Panel in 2013, adding the copper module to EPLAN Pro Panel in 2014 for cutting bus bars and other copper in control cabinets, they have enjoyed major productivity improvements in all phases of project execution. to provide the oil and gas, mining, renewable energy and transportation sectors among others with state-of-the-art power supply and conversion equipment and engineered solutions like motor control centers, switchgears, variable frequency drives, electrical houses and skid packages. BC and neighboring Alberta offer boundless opportunities for 3 Phase Power Systems, Inc. British Columbia, Canada’s westernmost province with its lush Pacific coastal rain forests and breath-taking mountains, is as resource-rich as it is scenic.

0 kommentar(er)

0 kommentar(er)